PROJECT OVERVIEW

Sargassum Eco Lumber is a groundbreaking initiative aimed at addressing the dual challenges of sargassum seaweed inundation and plastic pollution. By leveraging innovative technology, we are transforming sargassum seaweed and plastic waste into eco-friendly lumber, revolutionizing industries while fostering environmental sustainability.

PROJECT GOALS

ENVIRONMENTAL RESTORATION

Combat the sargassum crisis by repurposing seaweed, preventing its harmful accumulation on coastlines and minimizing its ecological impact.

PLASTIC WASTE REDUCTION

Divert plastic waste from oceans and landfills, converting it into a valuable resource for construction, furniture, and other applications.

INNOVATION AND CIRCULAR ECONOMY

Pioneer a solution that simultaneously addresses two major environmental issues, demonstrating the potential of the circular economy model.

SUSTAINABLE CONSTRUCTION

Provide industries with an eco-conscious alternative to traditional building materials, reducing their ecological footprint while maintaining structural integrity.

COLLABORATION AND AWARENESS

Foster partnerships with communities, businesses, and policymakers to collectively combat the challenges of sargassum and plastic pollution, raising awareness of sustainable alternatives.

KEY FEATURES

INNOVATIVE PROCESS

Utilize a proprietary process that combines sargassum and plastic waste to create durable, versatile, and eco-friendly lumber.

SCALABILITY

Design a scalable production model capable of accommodating large quantities of sargassum and plastic waste.

ENVIRONMENTAL IMPACT

Reduce greenhouse gas emissions by repurposing plastic waste and preventing coastal ecosystem degradation.

ECONOMIC VIABILITY

Offer a cost-competitive alternative to traditional materials, encouraging the adoption of sustainable practices in various industries.

OCEAN AND COASTLINES HEALTH

Contribute to the health and resilience of oceans by minimizing plastic pollution and addressing the sargassum phenomenon.

A SUSTAINABLE TRANSFORMATION

SOLAR DRYING SYSTEM

At the heart of our innovation lies a multi-step process that harmoniously merges cutting-edge technology with environmental responsibility. Our journey begins with the Solar Drying System, meticulously designed to reduce sargassum's moisture content to an optimal 14%. This dried sargassum, now free from excess water, undergoes a crucial grinding phase before being carefully stored in heavy-duty sacks within silos.

What sets our process apart is its profound impact on hygiene and sustainability. During the solar drying phase, the sargassum is sterilized, eradicating potentially harmful bacteria that could lead to undesirable fermentation. This sterilization process, achieved through controlled heat exposure, ensures that the final product meets the highest quality standards.

But our innovation doesn't stop here – it extends to strategic resource management. In times of peak sargassum arrival on Miami's shores, our system operates at full capacity. The ability to process substantial volumes of sargassum, effectively drying, grinding, and storing it for future use during scarcity, represents an ingenious way to manage this natural resource.

MOLDING MACHINE

At the core of our transformative journey stands the primary engine of our success – the Molding Machine. This groundbreaking machine operates tirelessly, capable of churning out benefits around the clock, 24 hours a day, 360 days a year. The Molding Machine is where the magic happens, where sargassum and recycled plastic unite to form the building blocks of a more sustainable future.

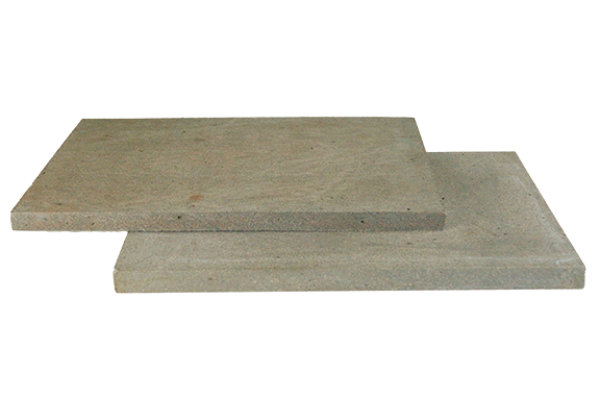

TRACTION

Our project is currently in the development phase, where we are actively engaged in designing and refining the technological aspects of all equipment involved. As part of our journey, we have successfully conducted initial pilot tests, showcasing the potential of our innovative product.

Through these pilot tests, we have manufactured sample materials, providing tangible evidence of the performance and quality of our Sargassum Eco Lumber. These demonstrations have garnered positive feedback, inspiring confidence in the project's viability.

As we propel forward on our mission to revolutionize sustainable construction and eco-friendly solutions. We are actively seeking partners who share our passion for innovation, environmental stewardship, and unparalleled growth.

By investing in our groundbreaking project, you not only become a vital part of our success story but also play a pivotal role in driving positive change on a global scale. Your support will fuel the expansion of our production capabilities, accelerate our market presence, and amplify our impact.